Insert moulding can be done either at the beginning of the moulding cycle or post moulding cycle, using secondary operation equipment to ensure every insert is positioned correctly and in exactly the same location within the moulding. The post moulding cycle can improve the strength of the moulded component. Custom built jigs are often required for precision location of the insert.

Press Fitting

There are three different processes for this type of insertion; Press-fitting Cold, Heat-staking and Ultrasonic Insertion. Press-fitting is where a cold insert is press fitted in to a plastic component. Heat-staking is where the insert is heated up and then pressed into the plastic component, allowing the plastic to melt and re-form around the insert. This will only work on

thermoplastic materials. Ultrasonic-insertion is where ultrasonic sound interference aggravates the insert while it makes contact with the plastic, causing the plastic to melt and re-form around the insert.

Screw Fitting

The insert is designed with an external thread so it can be rotated into the plastic component using various torque installation methods (screwing, milling machine, pneumatic driver, etc.)

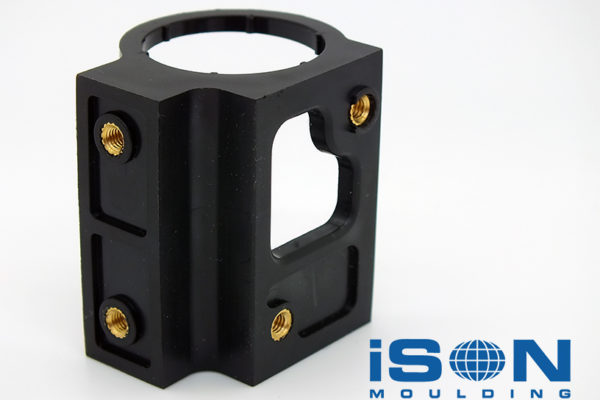

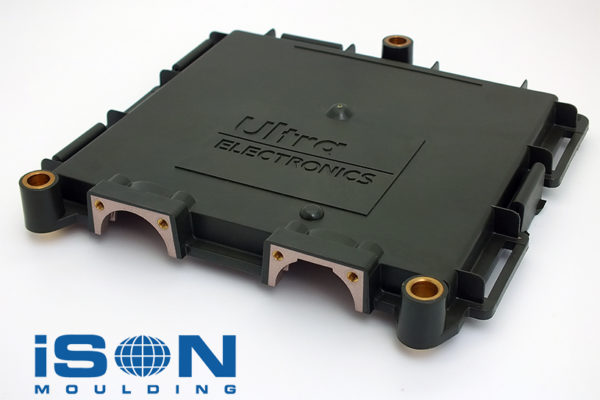

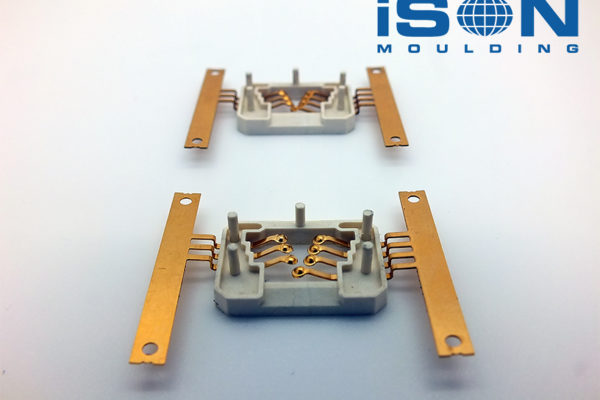

Insert Moulding

The mould tool is designed to have the insert hand loaded into the tool pre-moulding process. The plastic is injected in to the mould tool and forms around the insert under pressure. Once the molten plastic has solidified, the moulded component can be removed from the mould tool.screwing, milling machine, pneumatic driver, etc.)

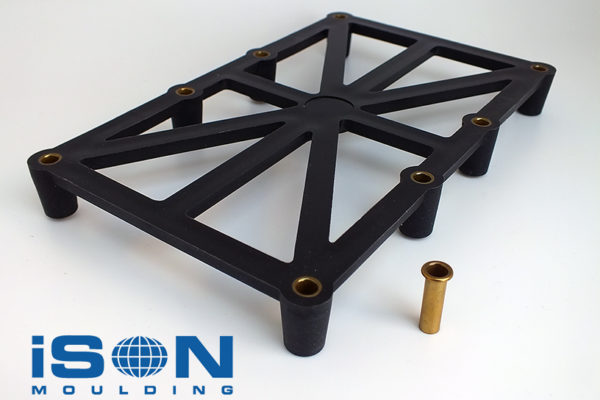

Anti-Creep Spacer Inserts

The benefit of this application is that a bolt can pass through the spacer stopping over stressing and allowing metal to metal clamping force for plastic components during assembly.

Bespoke Inserts

Bespoke insert can be made to any design and can come in a large variety of versions. For example, Hexagon version inserts provide a large surface area for the molten injected plastic to adhere to, this in turn gives the insert a very high torque reading and excellent pull out performance.

“Being able to incorporate either a performance plastic or a metal insert within the design of your product can be both beneficial and critical to it success. This is where Insert Moulding can provide the solution.”

Carl Anderson, Managing Director