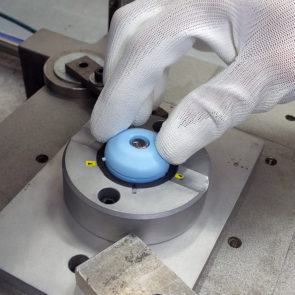

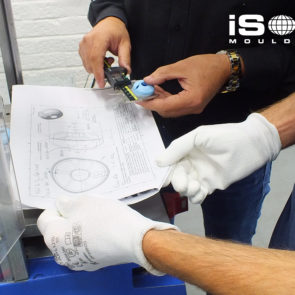

Our Ultrasonic Plastic Welding operation includes clean assembly areas, leak detection testing systems, strength testing, printing and packaging.

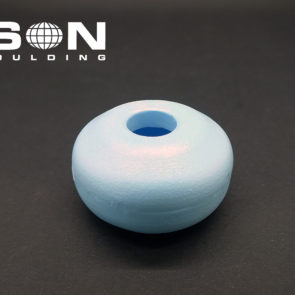

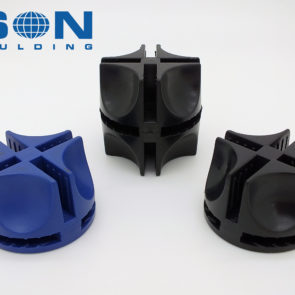

iSON Moulding is a technical moulder and possess extensive experience in the processing of most thermoplastic materials, with focused strengths in polypropylenes through to high temperature polymers like PEEK, PPS, and PSU.

Ultrasonic Plastic Welding, like many post moulding operations, is an area where iSON Moulding have made significant investment to ensure our understanding. This gives us the confidence to embrace thermoplastic projects that many moulding businesses might try to avoid, offering both injection moulding and ultrasonic welding under one roof.

Thermoplastic is ideally suited to ultrasonic welding, given its ability to transmit high frequency vibration. Rigidity and melting behaviour are an important part of material selection and are monitored throughout the production process.

“With passion and enthusiasm, we strive to manufacture perfect components. This drive is carried into other areas of our business and reflected in our Ultrasonic Welding capability. The demands of individual thermoplastic materials are rigorously controlled by our ultrasonic welding department, who possess the expertise and flexibility for a variety of challenging tasks. Our customers benefit from this and other in-house post moulding services, thus improving production lead times and price competitiveness.”

Carl Anderson

Managing Director, iSON Moulding Ltd

Click on images below to expand…