The importance of professional tool trialling

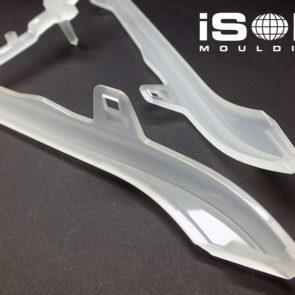

iSON Moulding understand how important the tool trial is in determining the capability of the tool which in turn produces quality components repeatedly. Many of our customers approach us for help and support in further developing an existing tool supplied by another moulder, which has already been delivered to the market place, that is failing to produce acceptable components. Misguidance from a lack of knowledge is always the root cause of the problem.

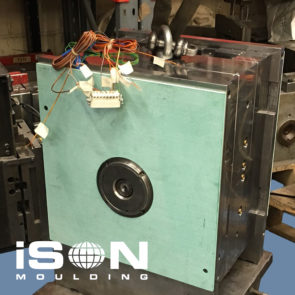

iSON Moulding offer a tool trialling service using skilled and knowledgeable staff to investigate the build and design, carry out modification where necessary and then re-trialling.

We always take the time to understand what our customers’ expectations of their product is and whether the process they are currently using is best suited to their needs.

“ The way that iSON Moulding is set up enables us to offer something unique to the customer, whether that is manufacturing skills or development services to support your needs – we are dedicated to the evolution of your plastic components.”

Carl Anderson, Managing Director