Heat Staking, also known as thermoplastic staking, is a process that uses heat to bond metal threaded inserts to post moulding plastic components. Unlike welding techniques, heat staking can bond plastics to other materials (e.g. metal, PCB’s) in addition to joining like or dissimilar plastics, and it has the advantage over other mechanical joining methods in eliminating the need for consumables such as rivets and screws.

This versatile technique enables iSON Moulding to add metal inserts and fasteners to a component post injection moulding, when options are limited through tool design and budgetary constraints.

Heat Staking is fast, economical and delivers consistent results…

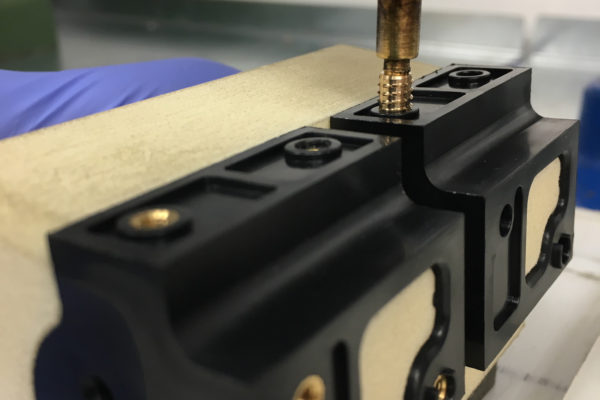

It is widely known that a plastic threaded area within a design will not give you the strength or the benefit of repeatable use within the component’s life. If you need to design a plastic component with strong reusable threads, then metal threaded inserts are the way to go.

Heat Staking vs Press Fit Process

The press fit process uses a cold metal insert/fastener and pushes it into a hole using a press. Because pressure and force are needed to achieve this, you generally find that the threaded insert can get damaged as well as the plastic component. Also, if this method is not executed perfectly, stress within the plastic can be added causing the plastic to split or crack in localised areas of the component.

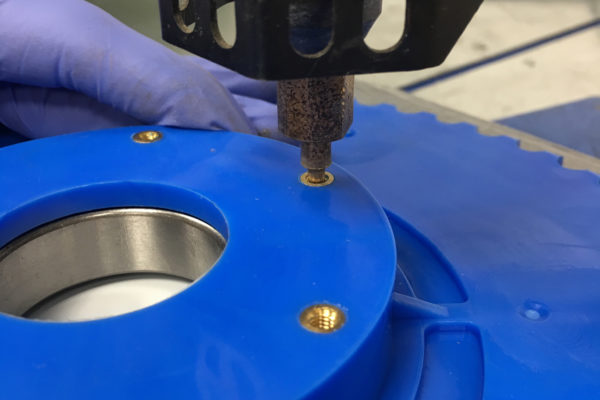

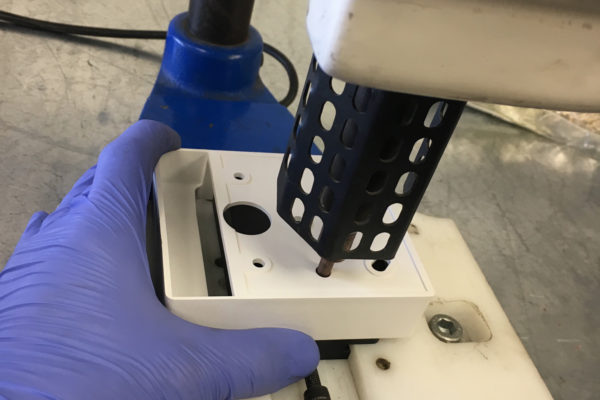

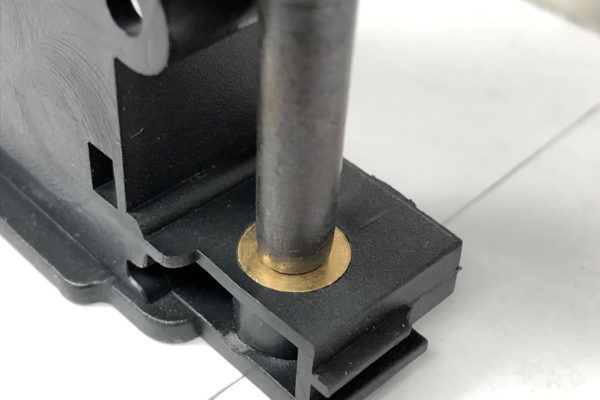

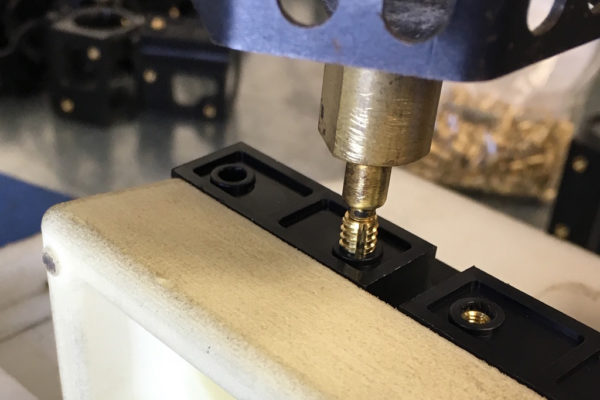

Instead of using pressure and force, the heat staking procedure presses the components into position under low pressure with the aid of rapid heat. The process is completed following contact between the chosen metal insert/fastener and the electrically heated staking press, with the press tip transferring conductive heat through the metal insert. This in turn melts the surrounding plastic as the threaded insert is gently pushed into place. Once the plastic has been allowed to cool down, the two components are mechanically bonded together.

Post Moulding Operations

At iSON Moulding we continue to answer our customers’ demands for further assistance beyond the injection moulding process. Through continuous investment in our post moulding operations we strive to fulfil your requirements. Our knowledge and experience of post moulding operations has evolved over the years to meet customer challenges and our plans for continuous improvement by investing in people and technology will help us to deliver against our customers specific needs.